Sliding Door Hardware for Detention Centers: Enhancing Safety and Security in Correctional Facilities

Sliding door hardware plays a crucial role in detention centers. These specialized components ensure smooth operation and enhanced security in correctional facilities. They’re designed to withstand intense use and potential tampering.

Proper sliding door hardware for detention centers is essential for maintaining safety and efficiency. It helps control access, prevent escapes, and protect both inmates and staff. The right hardware can make a big difference in daily operations.

Choosing the right sliding door hardware involves considering factors like durability, security features, and ease of use.

It’s important to select products that meet industry standards and regulations. Reliable hardware can help detention centers run more smoothly and safely.

Key Takeaways

- Sliding door hardware is vital for security and access control in detention centers

- Durability and tamper-resistance are key features to look for in detention hardware

- Regular maintenance of sliding door systems helps ensure long-term performance and safety

Overview of Sliding Door Hardware

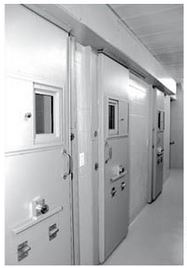

Sliding door hardware in detention centers combines durability, security, and smooth operation. You’ll find specialized components designed to withstand heavy use while preventing unauthorized access.

Types of Sliding Door Hardware

Types of Sliding Door Hardware

Detention centers use several types of sliding door hardware. Track systems guide the door’s movement. These can be top-hung or bottom-rolling.

Top-hung tracks keep the floor clear, while bottom-rolling tracks support heavier doors.

Rollers or wheels allow the door to move smoothly. High-quality bearings reduce friction and noise.

Door closers ensure doors shut automatically. This is crucial for maintaining security in detention settings.

Locking mechanisms are key components. They include electronic locks, key-operated locks, and manual locking bars. Many systems use a combination for added security.

Materials and Construction

Detention center sliding door hardware is built to last. Materials must resist wear, tampering, and corrosion.

Stainless steel is common for its strength and rust resistance. High-grade aluminum offers a lighter option without sacrificing durability.

Tracks are often made of hardened steel. This prevents bending or warping under constant use.

Rollers may use nylon or polyurethane for quiet operation. Metal rollers provide maximum strength but can be noisier.

Locking components use hardened steel alloys. These resist cutting and sawing attempts.

Finish treatments add extra protection. Powder coating or anodizing helps hardware resist scratches and chemicals.

Security Features

Security is paramount in detention settings. Sliding door hardware includes several safety measures.

Anti-lift devices prevent doors from being forced off their tracks. These are crucial for top-hung systems.

Tamper-resistant fasteners make it hard to dismantle hardware. Special tools are needed for installation and removal.

Fail-secure locks stay locked during power outages. This maintains security even if electrical systems fail.

Some systems use interlocking mechanisms. These prevent multiple doors from opening at once, controlling inmate movement.

Monitoring systems can be integrated into the hardware. These alert staff to door status and unauthorized attempts to open.

Compliance and Standards

Sliding door hardware for detention centers must meet strict regulations and safety standards. These requirements ensure the security and safety of both inmates and staff.

Industry Regulations

Detention and correctional facilities must follow specific guidelines for materials and hardware. You need to be aware of these rules when selecting sliding door hardware.

The American Correctional Association (ACA) sets standards for jail and prison construction. These cover door strength, locking mechanisms, and control systems.

Local building codes also apply to detention centers. You must check your area’s requirements for fire safety and emergency egress.

Some states have their own regulations for correctional facilities. It’s crucial to review these before choosing hardware.

Safety Certifications

Safety certifications prove that sliding door hardware meets industry standards. Look for products tested by recognized organizations.

ASTM International develops standards for detention hardware. Their tests check for durability, security, and performance.

UL (Underwriters Laboratories) certifies detention hardware. They focus on fire resistance and electrical safety.

The Builders Hardware Manufacturers Association (BHMA) grades hardware quality. Higher grades indicate better performance and durability.

When selecting hardware, check for these certifications. They ensure you’re using products that meet strict safety and security standards.

Customization and Integration

Sliding door hardware for detention centers can be tailored to specific needs and integrated with electronic systems. This ensures optimal security and functionality for each unique facility.

Tailored Solutions

You can customize sliding door hardware to fit your detention center’s exact requirements. Custom designs are important for facilities that need unique features. This may include specialized locking mechanisms, reinforced materials, or specific door sizes.

Manufacturers can adjust the hardware’s strength, durability, and security features. You can choose from various finishes to match your facility’s aesthetics. Some options allow for easy maintenance access while maintaining security.

Custom solutions also consider factors like noise reduction and smooth operation. This helps create a more manageable environment for both staff and inmates.

Electronic and Mechanical Integration

Your sliding door hardware can be integrated with electronic security systems for enhanced control. This integration connects door controls to central monitoring stations.

Electronic integration allows for:

- Remote locking and unlocking

- Automated schedules for door operations

- Real-time status monitoring

- Integration with alarm systems

Mechanical components work alongside electronic systems for fail-safe operation. This dual approach ensures doors can be manually operated if electronic systems fail.

You can integrate sliding door hardware with:

- Video surveillance systems

- Intercom systems

- Access control systems

This comprehensive integration improves overall security and operational efficiency in your detention center.

Security Features and Enhancements

Sliding door hardware in detention centers has advanced significantly. New technologies boost safety and control while streamlining operations.

Innovations in Locking Systems

Modern detention centers use sophisticated electro-mechanical locking systems for sliding doors. These combine electronic controls with mechanical strength. Key features include:

- Remote operation from a central control room • Biometric access controls (fingerprint or retinal scans) • Fail-secure mechanisms that lock doors during power outages • Time-delayed unlocking for added security

Some systems use multi-point locking, engaging bolts at several points around the door frame. This increases resistance to forced entry attempts.

Alarm Integration

Sliding door hardware now integrates seamlessly with facility-wide alarm systems. This provides:

- Instant alerts for unauthorized access attempts • Door status monitoring (open/closed/locked) • Logging of all door operations for auditing

Motion sensors near doors can trigger alarms if inmates linger too long. Pressure sensors in door tracks detect objects blocking proper closure.

Tamper-Proof Technologies

Manufacturers have developed several tamper-resistant features for sliding door hardware:

- Concealed mounting bolts and brackets • Hardened steel components resist cutting tools • Pick-resistant lock cylinders

Some systems use electronic current monitoring. This detects attempts to short-circuit control wires. Tamper-evident coatings on key components show visible damage if touched.

Anti-lift mechanisms prevent doors from being lifted off tracks. Reinforced door edges resist prying attempts.

Installation Best Practices

Proper installation of sliding door hardware in detention centers is crucial for security and functionality. Key factors include precise technical specifications, professional installation, and using the right tools and equipment.

Technical Specifications

Sliding door hardware for detention centers must meet strict requirements. Use only heavy-duty fixtures designed for high-security environments. Choose corrosion-resistant materials like stainless steel for longevity.

Ensure door frames are reinforced to support the weight of security doors. Select tracks rated for frequent, heavy use. Opt for tamper-resistant fasteners to prevent unauthorized removal.

Specify tight tolerances for door alignment to maintain security. Install robust locking mechanisms that integrate with electronic control systems.

Professional Installation

Hire certified technicians experienced in correctional facility work. They should understand security protocols and work efficiently within facility constraints.

Coordinate closely with facility staff during installation. Follow all safety procedures and maintain a secure work area.

Test doors thoroughly after installation. Check alignment, smooth operation, and proper locking. Make any needed adjustments immediately.

Document the installation process and final configuration for future reference. Train facility staff on proper operation and basic maintenance.

Tools and Equipment Needed

Use specialized tools designed for security hardware installation. This includes heavy-duty drills, precision measuring instruments, and tamper-resistant screwdrivers.

Bring portable welding equipment for any on-site modifications. Have a selection of shims and spacers to ensure perfect alignment.

Use a level and plumb bob for accurate positioning. Bring cleaning supplies to remove metal shavings and debris.

Keep spare parts on hand to avoid delays. Have a mobile workstation to keep tools secure and organized during the job.

Maintenance and Service

Proper upkeep of sliding door hardware in detention centers is crucial for safety and functionality. Regular maintenance checks and timely service help prevent failures and extend the lifespan of these critical components.

Routine Maintenance

You should inspect sliding door hardware weekly for signs of wear or damage. Clean tracks and rollers to remove dirt and debris that can impede smooth operation. Lubricate moving parts with a silicone-based lubricant to reduce friction and prevent corrosion.

Check locking mechanisms carefully. Ensure they engage fully and release smoothly. Tighten any loose screws or bolts. Look for cracks or deformation in door panels and frames.

Test emergency release functions monthly. Make sure staff can quickly override automatic systems if needed. Keep a log of all maintenance activities for future reference.

Service Intervals

Schedule professional service every 6 months for sliding door hardware in detention centers. These visits allow technicians to perform more in-depth inspections and maintenance.

During service appointments, experts will:

- Calibrate door sensors and controls

- Adjust alignment of tracks and rollers

- Test all safety features thoroughly

- Replace worn components proactively

Increase service frequency for high-traffic areas or doors subjected to harsh conditions. Keep detailed records of all service visits and repairs.

Replacement Parts

Stock essential replacement parts on-site to minimize downtime during repairs. Common items to keep on hand include:

- Rollers and wheels

- Track sections

- Locking components

- Control board fuses

Choose high-quality, durable parts designed specifically for detention center use. Avoid generic hardware that may not meet security standards.

Work with your door system manufacturer to identify critical spares for your specific models. They can provide guidance on which parts fail most often and require replacement.

Train maintenance staff on proper part installation procedures. Improper replacement can compromise door security and function.

Emerging Technologies

New technologies are changing sliding door hardware in detention centers. These advances improve security and make operations more efficient.

Smart Locks and Access Control

Smart locks are reshaping access control in detention centers. These locks use electronic systems to track staff and inmates. You can program them to allow or deny entry based on schedules or clearance levels.

Biometric scanners add another layer of security. They can read fingerprints or facial features to verify identity. This makes it harder for unauthorized people to enter restricted areas.

RFID technology is also gaining ground. Staff and inmates can wear RFID tags. These tags let you monitor movements throughout the facility in real-time.

Automation in Security Doors

Automated sliding doors are becoming more common in detention centers. These doors can open and close on their own, reducing the need for manual operation.

You can link automated doors to central control systems. This allows for quick lockdowns in emergencies. It also helps manage traffic flow through different parts of the facility.

Sensors play a big role in door automation. They can detect attempts to tamper with or force open doors. Some sensors can even spot hidden objects that inmates might try to pass through doorways.

Voice control is an emerging feature for automated doors. This hands-free option can be useful for staff members carrying items or dealing with uncooperative inmates.